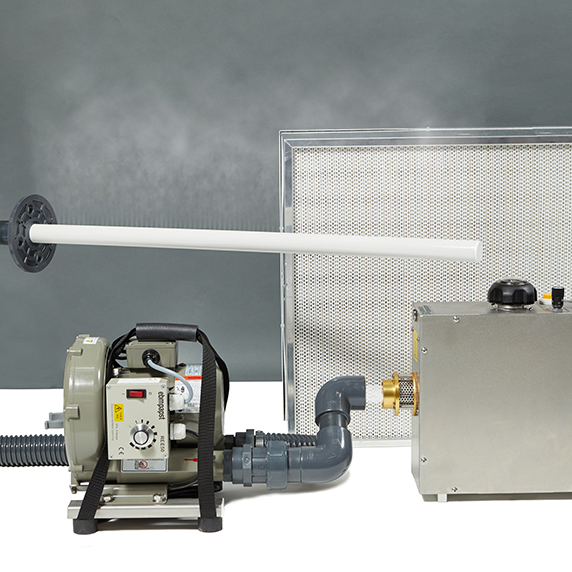

Positive Injection Pump

. Provides the force needed to inject aerosol into positively-pressured ducts.

. Cleanroom Certification.

. Aerosol is available up to 20 meters (65 feet) from the PIP for hard to reach places.

. Available speed control allows precise control of the sparge pipe aerosol curtain.

. Easily connect to Sparge Pipes or Aerosol Splitters.

. 50m3/hr @ 50mbar.

Product Specifications

Inject aerosol with variable speed control

The Positive Injection Pump (PIP) provides the user with a safe and reliable system for directing aerosol from a Thermal or Laskin-Nozzle Generator through a tube into the injection point. Speed control allows for regulation of the discharge velocity, which is essential when introducing aerosol through apertures of various size. The Positive Injection Pump (PIP) with adjustable swan neck inlet works best with the ATI family of aerosol generators.

Dimensions

(L x W x H):

41 cm x 26 cm x 29.5 cm

(16.1 in. x 10.2 in. x 11.6 in.)

Weight: 14.5 kg (32 lb)

Electrical:

SPB-2-110V-SC: 110-120V, 50Hz

SPB-2-220V-SC: 220-240V, 50Hz

Operating Conditions:

Temp %RH: 5-50 °C

30-80%

Pressure/Flow:

SPB-2-110V-SC: 58m3/hr @ 50mbar

SPB-2-220V-SC: 50m3/hr @ 50mbar

Speed Control: 10% – 100% range

Accessories

. PIP Case

. Tubing (51 mm x 10 m)

. Tubing (32 mm x 5 m)

You may also like…

-

Laskin Nozzle Generator ATI Model TDA 6D

. Airflow rates from 350 – 3500 m3/hr for a wide range of testing requirements.

. Flex-fuel capabilities, allows for the use of different reagents.

. Rugged Portability.

. Safe and reliable Operation.

. Built-in compressor.

. Easy operation for testing of Microbiological Safety Cabinets.

. Lightweight and rugged, ideal for remote locations. -

Photometer ATI Model TDA 2i

. Hepa Filter Testing ISO 14644-3.

. Lightweight, portable and rugged digital photometer

Large.

. 4.3″ LCD screen to display critical information.

. iProbe (optional) with 12 ft cable for hard to reach areas minimizes downtime.

. User settable aerosol noise suppression for more stable aerosol measurements.

. Printer (optional) available for reporting. -

Thermal Aerosol Generator ATI Model TDA 5D

. Hepa Filter Testing ISO 14644-3.

. Fast operation with a warm-up time of only 60 seconds.

. Widest range of System Flow Rates 850 – 120.000 m3/hr.

. Rugged Portability.

. Safe and reliable Operation.

. Flex-Fuel Capacity.

. Lightweight and rugged, ideal for remote locations.